Paper-based Wallpaper

Paper-based wallpaper: The Guide

When wallpaper was originally invented, it was made of leather, fabric and paper. Paper-based wallpapers are a real classic which has not lost any of its attraction despite the invention of modern non-woven wallpapers. Today, as the protection of the climate and the environment is more important than ever, paper-based wallpapers are increasingly coming into focus because of their resource-saving and sustainable characteristics. They are breathable and moisture-permeable which promotes a healthy room climate. In addition, the huge selection of patterns and motifs continues to surprise and delight wallpaper lovers.

Table of Contents

- What is paper-based wallpaper?

- How is paper-based wallpaper produced?

- Which printing processes are used for paper-based wallpaper?

- Which characteristics distinguish paper-based wallpaper from non-woven wallpaper?

- Which paste/adhesive is used for paper-based wallpaper?

- How is paper-based wallpaper put up correctly?

- Why is it so important to observe specific soaking times for paper-based wallpapers?

- How is paper-based wallpaper removed?

- How is paper-based wallpaper cleaned?

- Which paper factories produce the base paper for wallpaper manufacturers?

- Our tips: Ideas around paper-based wallpaper

What is paper-based wallpaper?

Paper wallpapers consist of one or more layers of paper. The surface/upper layer can be printed, coated or structured. A distinction is made between wallpapers made of simplex paper, duplex paper, wood-chip wallpaper and paper wallpaper as base material.

Simplex paper

Simplex paper is a single-ply, wood-free or wood-containing paper with a relatively low strength. The grammages of this paper grade range from 100 to 130 g/m². For high-quality wallpapers, Simplex papers play a less important role. They are generally only used for very inexpensive wallpaper products.

Duplex paper

Duplex paper is a two-layer paper consisting of a wood-free surface (pulp) layer and a wood-containing bottom layer (usually recycled paper). The top and bottom layers are "wet couched", i.e. pressed. A starchy adhesive is generally used for this process. Duplex papers have a much higher strength, with grammages of 130 to 180 g/m².

Wood-chip wallpaper

Wood-chip wallpaper is characterised by its rough surface. This is due to wood chips being added between three layers of paper. Depending on the degree of grain, fine, medium or coarse structures are formed. Wood-chip wallpaper can be painted over several times. This popular universal wallpaper type was invented in 1864 by German pharmacist Hugo Erfurt.

Paper wallpaper as base material

Like non-woven material, paper can also just be the base material of a wallpaper model. Coatings of plastic/PVC can be applied to this carrier layer, which is why these wallpaper models are known as vinyl wallpaper. In addition, the paper carrier is also the basis for high-quality grass and cork surfaces, bamboo and other natural materials.

How is paper-based wallpaper produced?

The production process of paper-based wallpaper includes several steps. Wood is the basic raw material, and recycled paper is added in the production process which consists of the following steps: cellulose extraction, sheet formation, pressing and drying as well as surface coating.

Wood as primary raw material

Renewable wood is the primary raw material for paper-based wallpaper. The main types of wood used in this process are softwoods such as spruce, pine, larch and fir. In Scandinavia in particular, the sustainable and controlled forestry industry is geared to the wallpaper industry which meets strict ecological requirements.

Waste paper as an addition

In order to save energy and water in paper production and at the same time conserve raw material resources, a specific proportion of recycled paper is used. For this purpose, the waste paper is treated (recycling of the paper fibres) and the fibres obtained from this process are mixed with the fresh fibre paper.

Extraction of cellulose

Cellulose is the most important component of the cell walls of plants. To obtain pure cellulose, the wood is first cut, sanded and ground. With the help of chemical sulphite and sulphate processes, the soluble substances can then be separated from the cellulose so that only pure cellulose fibres remain. These form the basis for the production of paper-based wallpaper.

Sheet formation, pressing and drying

The production of paper-based wallpaper relies on paper machines. Cellulose, recycled paper fibres and additives (glue, dyes) are finely ground, processed with water to form a pulp (stock) and spread between two sieves. At the same time, the lengths of paper are formed. As the water drips off, "paper fleece" is created, which is then pressed out with rollers. To remove residual water from the intermediate product, it is dried by hot steam.

Surface coating

In order to improve the print quality of paper-based wallpapers, the surface finish consists of coating paint which usually contains kaolin clay and titanium dioxide. Paper treated in this way is referred to as "coated paper". Compared to uncoated paper, the surface appears much more uniformly smooth and stable.

Which printing processes are used for paper-based wallpaper?

The individual look, feel and quality of paper-based wallpapers depends on the printing process. The common traditional printing processes include gravure printing, flexo printing, screen printing and surface printing.

Gravure printing

The forerunner of gravure printing was copperplate engraving, one of the oldest printing processes. The printed image is engraved or lasered into a printing roller. The ink is applied to the printing device where it settles in the depressions. Excess ink is removed. The adhesion forces between paper and ink and the application of high contact pressure ensure the ink transfer.

Flexo printing

Flexographic printing is a modern letterpress process. Special roller coverings made of photopolymer or rubber are attached to an impression cylinder. An anilox roll is used to apply low-viscosity printing inks to the rubberised roller covering. An impression cylinder guides the wallpaper which is brought together with the roller covering.

Screen printing

The printing plate for rotary screen printing is designed as a cylinder. The length of wallpaper is moved along under the cylindrical printing plate. The cylinder rotates synchronously with the movement of the paper in one direction. A fixed printing squeegee inside the cylinder moves the printing ink (which is continuously pumped into the cylinder) onto the paper.

Surface printing

Surface printing is a traditional process involving high pressure. The printing inks bound with glue are transferred to the paper surface by pattern rollers made of wood with felt, rubber or metal profiles. Each printing ink of a pattern requires its own roller. The printed image boasts soft transitions and gently merging colours.

Which characteristics distinguish paper-based wallpaper from non-woven wallpaper?

Paper-based wallpaper is considered to be environmentally friendly, harmless to health, highly breathable and moisture-regulating. However, in contrast to non-woven wallpapers, paper-based wallpapers are not suitable for wet rooms.

Environmentally friendly thanks to recycled paper

Recycled paper or recycled fibres are used for the production of paper-based wallpaper. This meets today's requirements for sustainability and boasts environmentally friendly characteristics. Even if they are just an addition, renewable raw materials are specifically protected. Other advantages to mention are saving water, energy, CO2 emissions and waste in the manufacturing process.

Highly breathable

Wallpapers made of paper (in all layers) are breathable and create a pleasant room climate. They can absorb environmental substances and moisture without trapping them. This means constant circulation and prevents harmful micro-organisms from settling or fungi (mould) from forming under the wallpaper.

Moisture-regulating

Paper wallpaper absorbs moisture from the air in the room and gradually releases it again. The open-pored surface contributes to a pleasant room climate but also has an effect on cleanability. As a result, paper-based wallpapers are usually not washable. Exceptions: wallpapers with a paper carrier sealed with waterproof plastic coating (vinyl wallpapers).

Harmless to health

Pure paper models without special surface coatings such as PVC are great for the health-conscious amongst us. The reasons for this fact is that they contain no synthetic fibres or softeners. As a result, the risk of allergies and health complaints tends to be close to zero.

Less suitable for bathrooms

Since pure paper-based wallpapers absorb moisture, they are unsuitable for damp rooms and wet areas such as bathrooms. The penetration of moisture, especially of steam created during bathing and showering, can make the wallpaper come off the wall or promote the formation of mould. Suitable alternatives are non-woven wallpaper models or vinyl wallpaper.

Tearing test

If you are unsure what kind of wallpaper you are dealing with, you can do the tearing test. Tear off a small piece of wallpaper about an inch long. With paper wallpaper, the rip is uneven and the paper fibres are very short. In non-woven wallpaper, on the other hand, the rip is characterised by long, straight fibres that look a bit like needles.

Which paste/adhesive is used for paper-based wallpaper?

Wallpapering paste containing starch or cellulose or adhesive for non-woven wallpaper are all suitable for paper-based wallpaper. The types of wallpapering paste mentioned here are harmless to the environment and our health.

Paper paste containing starch

This is a powder that contains starch from various plants (e.g. potatoes and grains). The paste powder is mixed with water, increases in volume and reaches a jelly-like consistency. Paper paste containing starch is the oldest solution, but it is of lower quality than more modern types of adhesive.

Paper paste containing cellulose

For those who prefer a high-quality solution, paper paste containing cellulose is the answer. The powder consists of pure methyl cellulose, usually obtained from cotton. Methyl cellulose can be mixed with cold water. The solution is clear and colourless, neutral in taste and smell and is even used in the food industry. The paste requires a specific time to develop (swelling time).

Paste for non-woven wallpaper

Although this specific powder adhesive is intended for non-woven wallpaper, it can also be used for paper-based models. For this purpose, the recommended mixing ratio with water given on the package is adapted slightly. Compared to non-woven wallpaper, about 25% more water must be added to the powder if it's used for paper-based wallpaper. The consistency of the paste is slightly more fluid, as paper-based wallpapers require a certain soaking time.

How is paper-based wallpaper put up correctly?

Hanging paper-based wallpaper is not difficult at all. The important steps can be described as follows: mixing the wallpapering paste, applying it to the wallpaper, letting the wallpaper soak and putting up the prepared length of wallpaper.

Mixing the wallpaper paste

Water and paste powder are mixed according to the information on the packaging. The amount of paste needed depends on the area to be wallpapered. The powder should slowly be added to the water while stirring until the paste has a homogeneous consistency. The required swelling time for the paste is approximately 15 minutes. After the swelling time, the finished paste needs to be stirred again.

Applying paste to the wallpaper

The pre-cut length of wallpaper is placed "face down" on the trestle table. Alternatively, an extendable table made of plastic, metal or wood can also be used. The paste is applied evenly and generously with the paste brush, starting from the centre and including the edges. Then the length is folded from the outer ends towards the middle. This prevents the paste from drying out too quickly, especially at the edges.

Soak the wallpaper

Details regarding the required soaking time can be found on the packaging. Depending on the room temperature, it is usually between 3 and 5 minutes for each pasted wallpaper strip, but can sometimes require up to 10 minutes. The specified soaking time must exactly be adhered to for each individual strip.

Hanging the lengths of wallpaper on the wall

The first length has to be put up along a (pre-drawn) plumb line. After the soaking time, the wallpaper strip is unfolded at the upper end and pressed lightly against the wall, leaving a small overhang at the ceiling. Then the lower end is unfolded and pressed onto the wall. The wallpapering brush is used to smooth out the wallpaper from the middle to the edges.

Why is it so important to observe specific soaking times for paper-based wallpapers?

Paper-based wallpaper expands during the soaking period, the strip becomes slightly wider and longer. If soaking times are different for various strips of wallpaper, it can lead to creases, open seams after drying, blistering and incorrect pattern alignment at the edges.

Creases after drying

If the soaking time is too short, the length of wallpaper continues to expand on the wall until it reaches its final length and width. When drying, unsightly creases appear due to the contraction. These are difficult or impossible to remove later.

Open seams after drying

If soaking times are too short and the room temperature is too high or there is a draught, open seams will appear after drying. If the wallpaper has not been able to expand completely and dries faster than the paste due to draughts or room temperatures above 18 degrees, the drying tension causes seams to burst.

Air bubbles

Air bubbles are another result of short soaking times, as the wallpaper continues to expand on the wall. This is due to the wood fibres in the paper. If the wallpaper dries too quickly as a result of high room temperatures or draughts, air is trapped which results in the formation of bubbles.

Incorrect pattern alignment at the edges

For patterned wallpaper, if individual strips of wallpaper have different soaking times, the edges will not align properly. These differences in expansion are tricky to deal with, making the wallpapering process considerably more difficult and/or longer because there might be no other solution than to start again.

How is paper-based wallpaper removed?

Paper-based wallpaper is firmly attached to the surface of the wall. To remove it, the wallpaper is soaked with a sponge or spray bottle and should be left for a while before scraping it off with a spatula.

Soaking wallpaper

A mixture of washing-up liquid and water has proven to be effective for moistening wallpaper. The paste-dissolving effect is increased by using warm water. Alternatively, there are various wallpaper stripper products which are usually diluted with water. The wallpaper should soak for approx. 15 minutes, because the better the liquid can penetrate the paper, the larger the pieces that will detach from the wall.

Remove pieces of wallpaper with a spatula

After the soaking time, the painter's spatula is placed along the seam of a wallpaper strip and pushed under it. Ideally, large pieces can be scraped off, sometimes even a part of an entire length. If there are older wallpaper layers underneath, they need to be soaked again and the whole process has to be repeated.

How is paper-based wallpaper cleaned?

Pure paper wallpapers are usually only water-resistant, but not washable. This means: avoid detergents, dab stains carefully and use heat to remove grease stains.

Avoid detergents

On paper-based wallpapers with unsealed surfaces, cleaning agents should not be used at all. They can damage or even dissolve the surface, blur the colours and cause them to fade. Washing up liquid is also not an option here. Only pure water should be used.

Carefully dab off stains

Absolutely fresh and water-soluble stains can be carefully dabbed off with a damp cloth. Please do not rub as this will roughen the surface of the paper-based wallpaper and damage it irreversibly. If paste has ended up on the front of the wallpaper during wallpapering, it must be removed immediately to avoid permanent stains.

Get rid of grease stains with heat

A proven household remedy can help remove fresh grease stains. Use blotting paper and press it onto the stain. Now carefully iron over the grease stain (moderate heat!). The heat should liquefy the grease, which will then be absorbed by the blotting paper.

Which paper factories produce the base paper for wallpaper manufacturers?

Germany, Finland and Sweden are the leading countries for the production of wallpaper. The best known companies include Metsä Board, Kämmerer Paper, Stora Enso Paper and Ahlstrom-Munksjö.

Metsä Board, Finland

An unerring focus on sustainability and ethical practices are the hallmarks of the Finnish company Metsä Board, which has its origins in a wood grinding mill founded in 1868. Today, the company produces high quality fresh-fibre cardboard, wallpaper, packaging and cooking papers.

Kämmerer Paper, Germany

Kämmerer is one of the most renowned globally active manufacturers of special papers. It is known for its openness to innovation and constantly strives for improvement. The German company proudly looks back on a tradition of more than 200 years.

Stora Enso Paper, Sweden

Stora Enso Paper is a Swedish company in the forestry, paper and packaging industry. It was established in 1998 through the merger of Swedish company Stora (mining and forest products) and Finnish company Enso Oyj. It's one of the world's largest producers of paper and pulp.

Ahlstrom-Munksjö, Finland

The forestry companies Ahlstrom and Munksjö, founded in Finland at the end of the 19th century, merged in 2017 to form Ahlstrom-Munksjö. It is amongst the world market leaders for fibre-based materials and solutions, including wallpaper papers and non-woven wallpaper products. Ecological process engineering plays a decisive role in the production process.

Our tips: Ideas around paper-based wallpaper

- Applying paper-based wallpaper onto wood: With a carefully chosen decorative paper-based wallpaper, cupboards, chests of drawers or screens made of wood get a new lease of life. Please note that wood can swell due to the moisture in the paste. The paste should not be applied too thickly. For thin wood, a primer layer might be a good idea. Applying the wallpaper to both sides of the wood is also a solution to avoid warping.

- Applying paper-based wallpaper onto wood-chip wallpaper: This is not a good idea because the wood shavings can push through thin paper-based wallpaper, or both wallpaper types can come off the wall at the same time. Hence our tip: First remove the wood-chip wallpaper and prepare the surface, then put up the new paper-based wallpaper.

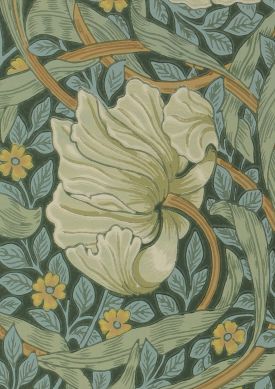

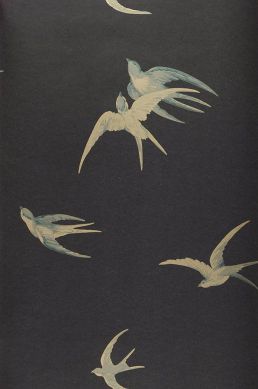

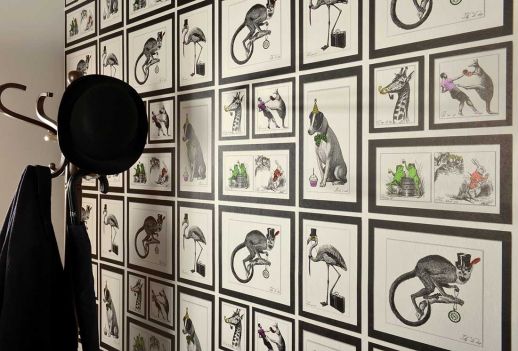

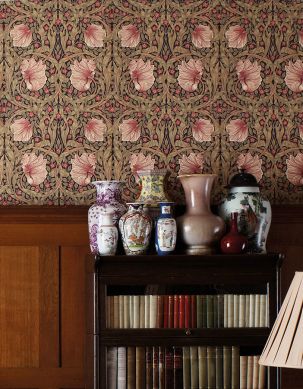

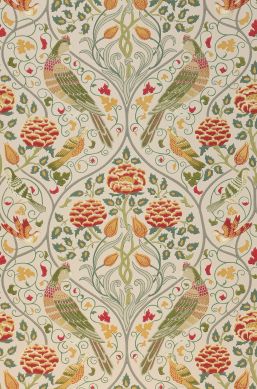

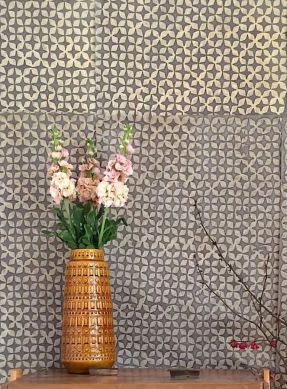

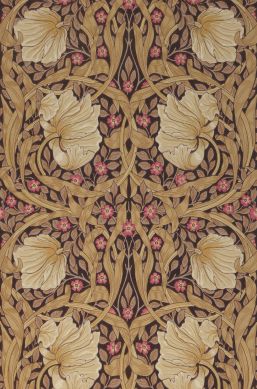

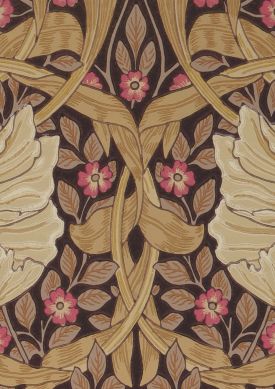

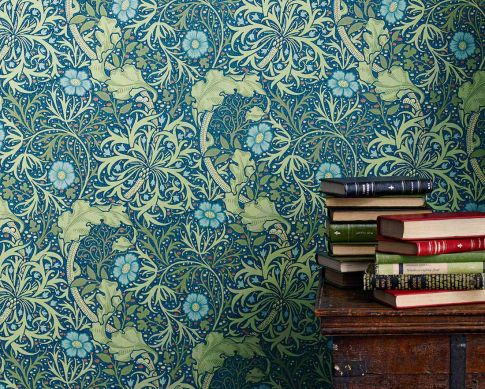

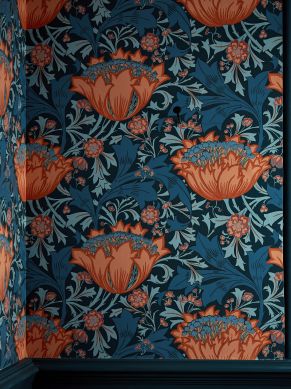

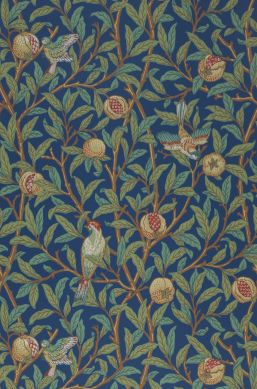

- Breathable paper wallpaper in the bedroom: You can create a healthy bedroom where air and moisture can circulate freely by simply using an attractive paper-based wallpaper. The huge variety of designs allows for the creation of opulent baroque night chambers, oriental oases or intoxicating flower paradises, to name but a few examples.

- Waterproof sealing with liquid wallpaper protection products: To seal paper-based wallpaper in order to protect it from moisture and dirt, the market offers spreadable wallpaper sealants, also known as dispersion primer. It is recommended that you do a suitability test on a small piece of wallpaper to check the compatibility with your individual wallpaper and its colour print.